Multipurpose Feeder Card Stock Labels Plastic Bag Feeder Sorter Friction Feeder Sorter

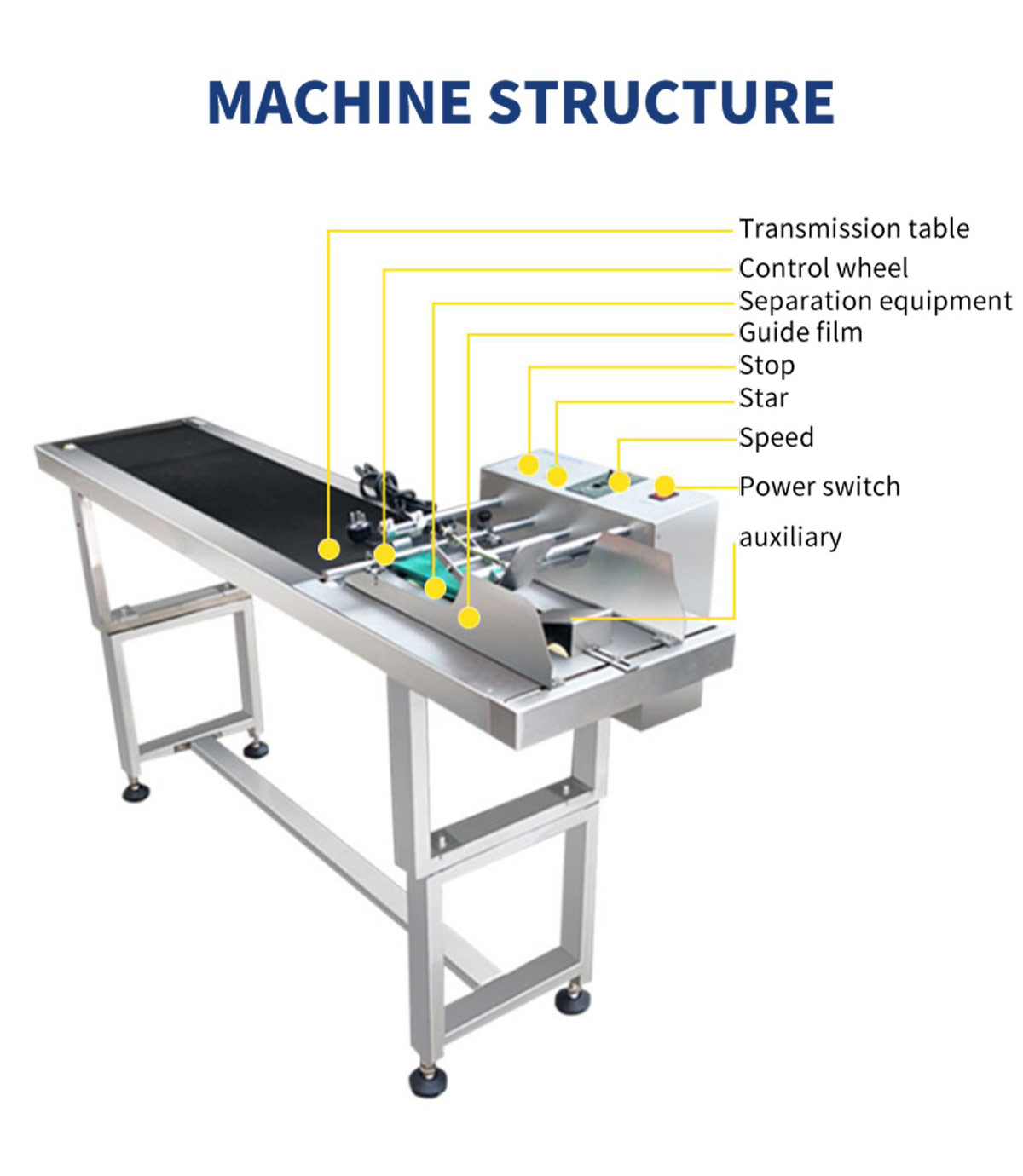

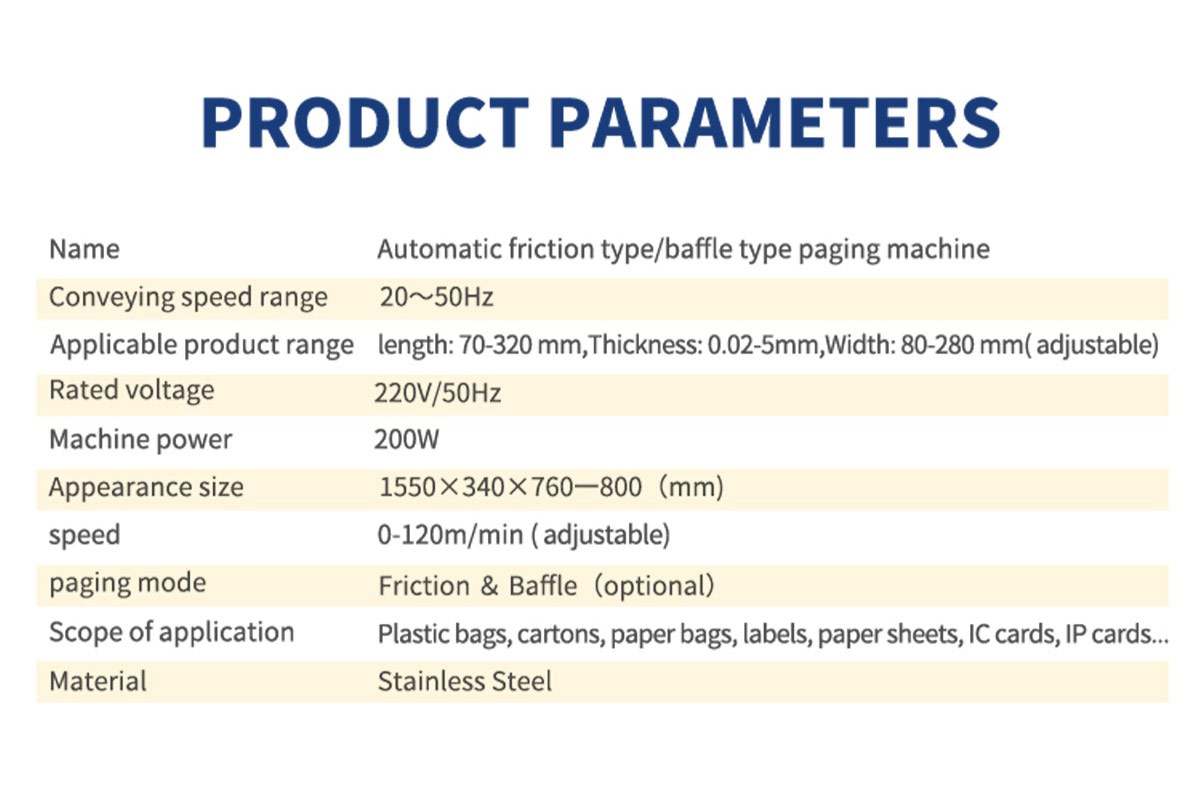

Name: paging machine for inkjet printers

Customization: support customization, size, speed

Standard size: 1500mm*340mm*(760mm-800mm)

Speed: 0-120 m/min

Material: Stainless steel

Minimum order quantity: 1

Packing: plastic box+carton+foam

Delivery time: 7-20 working days

| Model | High-speed plastic bag separator |

| Size | 1500mm*340mm*760mm-800mm(standard) |

| Belt width | 200mm (can be customized) |

| Speed | 0-120m/min (adjustable) |

| Power supply | 200W |

| Machine material | Industry Standard Stainless Steel |

It can be independently applied to the sorting and separation of food, paper and other items. The fully automated operation mode saves time and effort and ensures the production speed. Used in conjunction with the inkjet printer, it can automatically separate stacks of various specifications of plastic bags, packaging bags or cards, divide them into single pieces and transfer them to the conveyor belt, assist in completing the inkjet printer identification, and give full play to the inkjet printer and laser machine. The advantages of high-speed jet printing greatly improve the labeling efficiency of small packaged products and ensure product output.

1. Packaging bags: plastic bags, cartons, paper bags, labels, paper sheets, etc.

2. Card type: IC card, IP card, etc.

1. All stainless steel body: all stainless steel body, easy to dissipate heat, anti-aging, non-deformation, safe and firm, beautiful and durable

2. Intelligent conveying adjustment: The conveying speed of the conveyor belt can be adjusted according to its own actual needs, which can effectively improve work efficiency, save manpower and material resources, and reduce costs.

Features

1. Imported frequency conversion stepless speed regulation, high-speed automatic paging 60-600 pieces/min.

2. It can automatically count, or set the number of pages by itself, and automatically stop when the number of pages is required. The social range is 1-9999 (it needs to be shared with inkjet printers and laser machines).

3. High paging speed, high positioning accuracy and high production efficiency.

4. The structure design is qualified, and the replacement of wearing parts is simple and quick.

5. Optional accessories: automatic feeding device, separate counting and stop signal source for paging machine

Supports customizable content:

1. Lengthen and widen

2. The belt is perforated for egg transportation

3. Stainless steel unloading table can be added

4. An assembly line with a workbench can be added on both sides of the conveyor belt

5. Customizable rail guardrail

6. Roller conveyor

7. Various colors of belt customization