Best Quality Laser Metal Marking Machine Factory

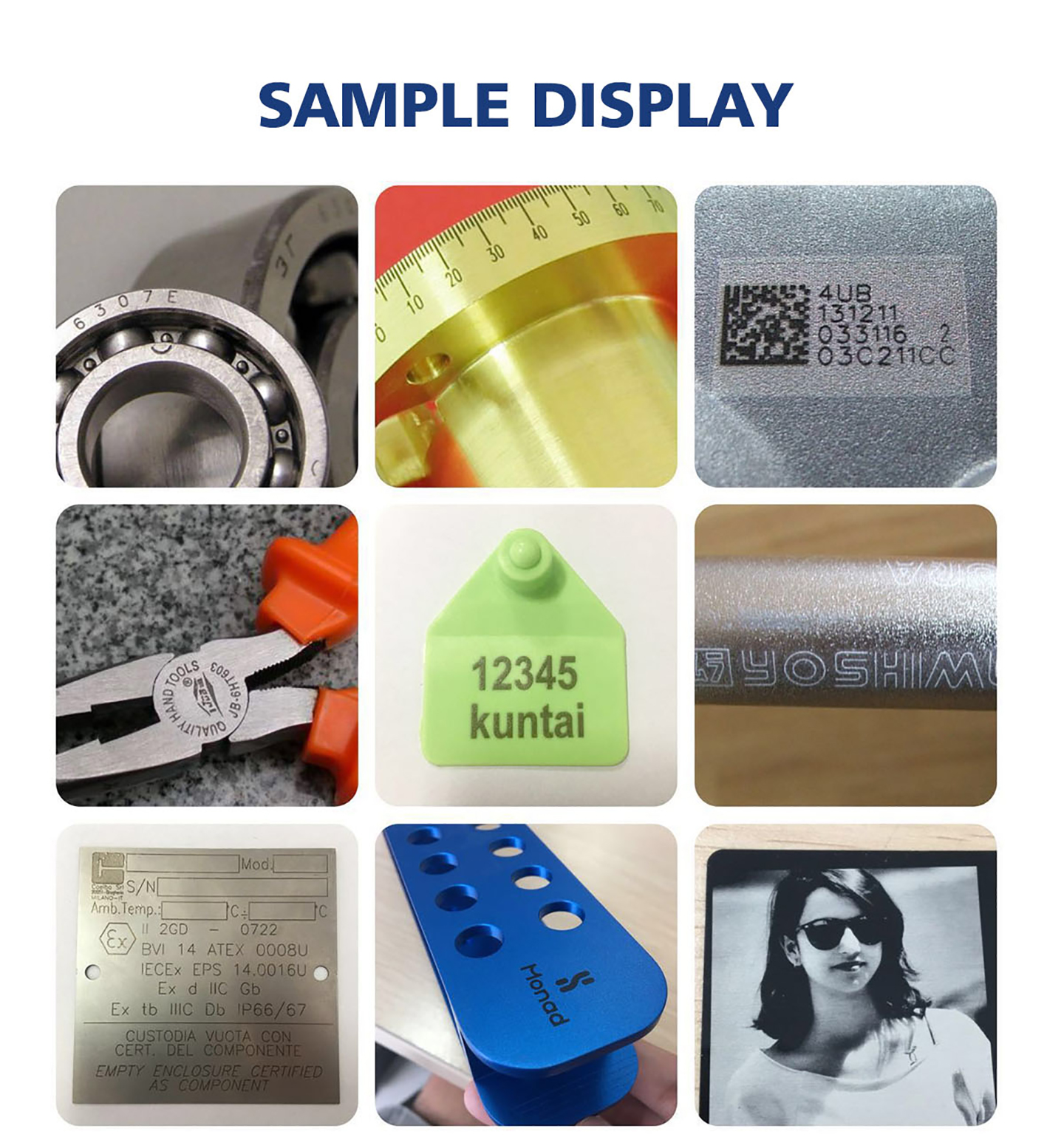

Widely used in integrated circuit chips, computer accessories, industrial bearings, clocks, electronic and communication products, aerospace devices, various auto parts, home appliances, hardware tools, molds, wires and cables, food packaging, jewelry, tobacco and military affairs, etc. Field graphics and text marking, as well as high-volume production line jobs.

1. It can process a variety of metal and non-metal materials. In particular, it is more advantageous to mark high hardness, high melting point and brittle materials.

2. It belongs to non-contact processing, does not damage the product, has no tool wear, and has good marking quality.

3. The laser beam is thin, the processing material consumption is small, and the processing heat affected zone is small.

4. High processing efficiency, computer control, easy to realize automation.

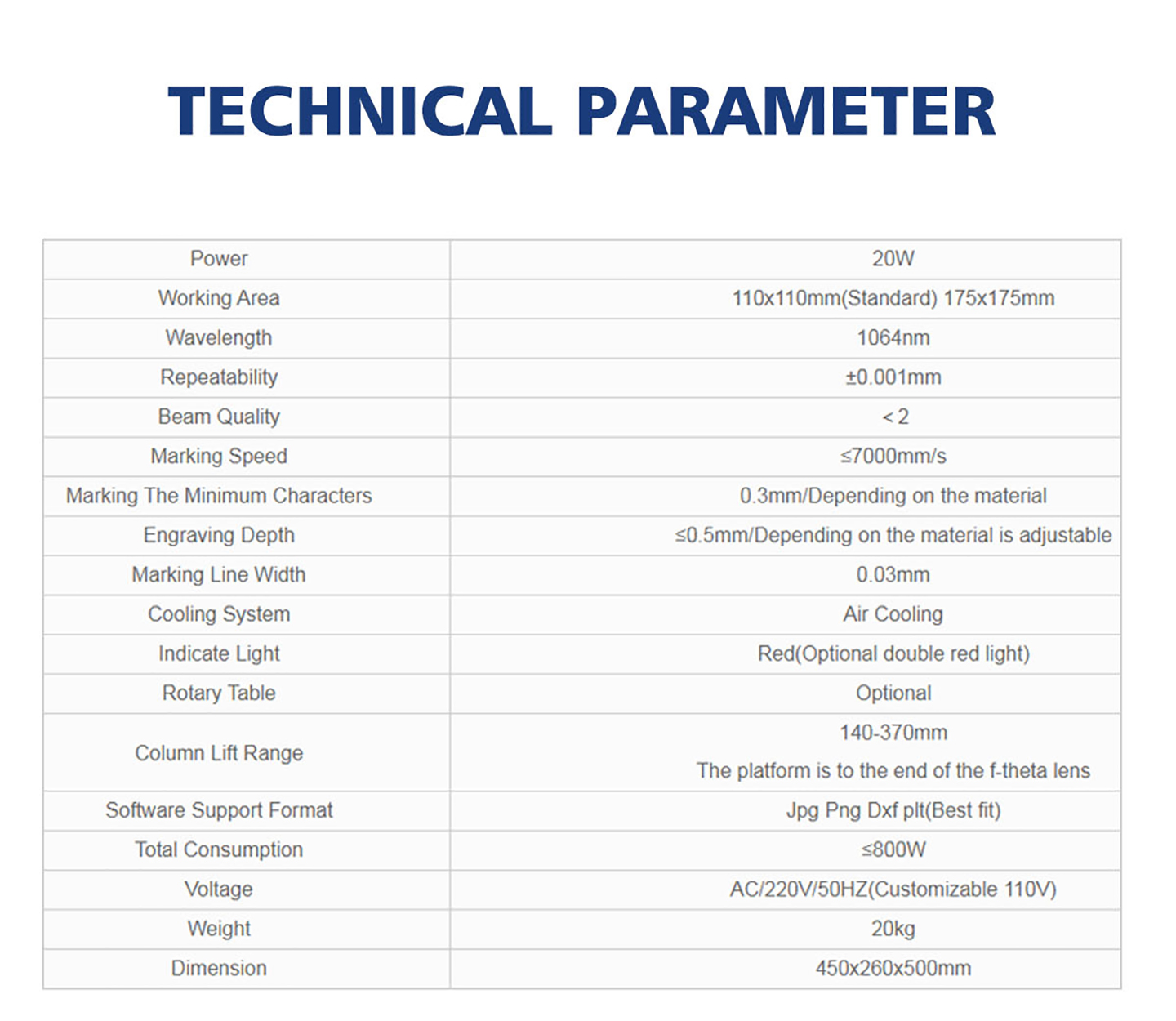

Laser | RAYCUS | Laser power | 18W~20W (Subject to factor inspection) |

Laser wavelength | 1064nm | ||

Beam quality | <2 | ||

Indicating light | Red li^ht | ||

Galvanometer | SKYLER | Marking speed | W5000mm/s |

Repeat accuracy | ±0.01mm | ||

Field lens | JGZ | Marking range | HOmmXllOmm |

Marking line width | 0.17mm | ||

Marking control system | KELIER | Support operating system | Windows operating system |

Support file format | PLT, Al, dxf, bmp.jpg | ||

Sport control | (Optional) | ||

Lifting mechanism | KELIER | Lifting stroke | 165mm-410mm |

Exercise mode | Manually up | ||

Workbench and tools | KELIER | Workbench | One-piece aluminum alloy :200mmX213rrm) |

Fixture | (Optional) | ||

Cooling system | KELIER | Cooling method | Finned radiator+forced air cooling |

Power supply system | KELIER | Operating Voltage | 110V/230V, 50/60HZ |

Peak power | 20-30W | ||

Equipment size and packaging | KELIER | Equipment size | 390mmX215mmX603mm |

Total Weight | 15KG | ||

Package dimensions | 755mmX590mmX360mm | ||

Packing material | Pearl cotton + corrugated paper box |

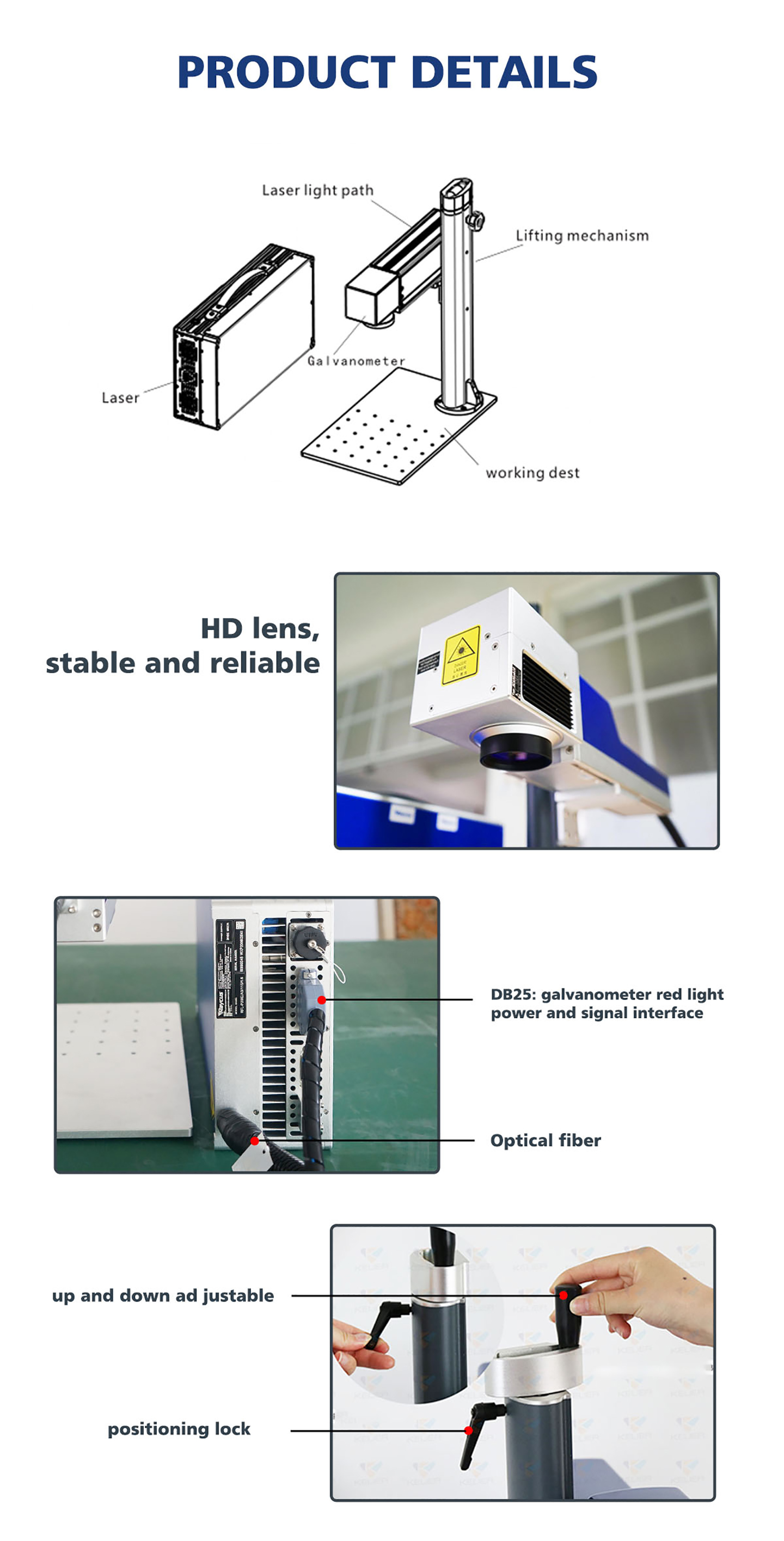

The equipment adopts Raycus laser, the control system adopts the golden orange control card and marking software, the galvanometer adopts the Skyler galvanometer, the field mirror adopts the lattice subfield mirror, and the core accessories are all well-known domestic brands.

The host adopts an integrated design, which integrates core components such as laser, control card, and power supply, making the host smaller. The optical path adopts a compact design, and the size is only half the size of the traditional optical path. The size of the whole machine is 390mmX215mmX603mm, and the weight of the whole machine is about 15KG.

The aluminum alloy fin heat-conducting chassis is designed, and the laser and control board power supply system adopts a separate design, so that the heat can be quickly conducted to the aluminum alloy chassis fins, and then the heat is taken away by the forced air cooling system to ensure that the equipment The components work in an ideal temperature environment, which greatly improves the stability and reliability of the equipment

Common process

1. Fiber laser annealing marking

Fiber laser annealing marking is a permanent mark caused by heat generated by a laser without removing or damaging the material. Annealed marking is used on all carbon-containing metals and when exposed to heat reduces the thermal effect of the carbon in the material to the surface, resulting in a color change.

2. Fiber laser ablation, surface removal

Fiber laser ablation, surface removal, is the ablation or vaporization of material surface coatings by laser thermal energy to create contrast without damaging the substrate. This process is usually used to remove materials such as surface paint, anodized aluminum, etc. Common applications are automotive dashboards, backlit buttons, etc.

3. Fiber laser engraving

Fiber laser engraving is a laser-induced ablation of the workpiece or material surface by laser melting or evaporating the substrate through the high-energy heat of the laser beam, so the laser beam removes the material. Engraving is a method for creating durable, direct, permanent markings that are counterfeit-proof and wear-resistant and corrosion-resistant.

Chengdu Kelier Electronic Co., Ltd.

It has more than 20 product lines, supports OEM/ODM customization, supports boot interface customization, and packaging customization.

Participated in international exhibitions more than 10 times, won the favor of customers from many countries, and reached long-term cooperation with customers from many countries.

Chengdu Kelier Electronic Co., Ltd. Won the national high-tech enterprise certificate, a number of product certificates, product patents, and has a number of trademarks.

The products are made of high-quality materials and imported accessories from the United States.

Kelier has many years of export experience, rich export experience, supports a variety of transportation methods, sea, long distance, air, etc., and provides professional and high-quality export services.